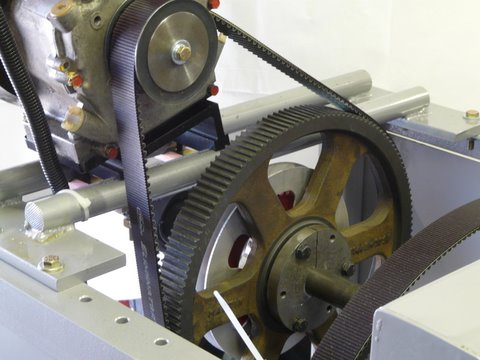

THIS E-BAY ITEM IS A CLUTCH TYPE INERTIA ACCELERATION DYNO. IT USES THE CLUTCH ON YOUR ENGINE.

CLICK HERE TO GO TO E-BAY LISTING

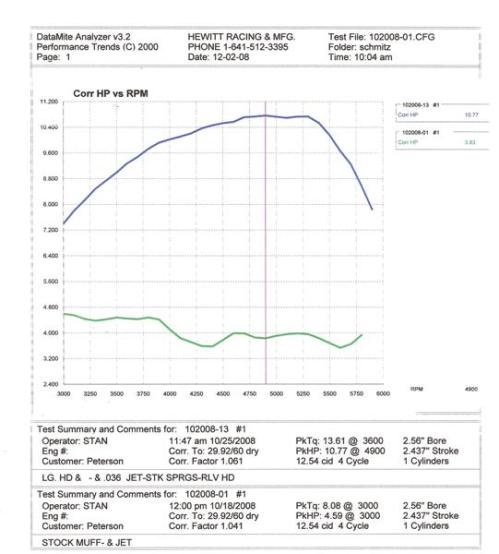

IT WILL COME WITH A 30 HP FLYWHEEL. IT COMES WITH A ADJUSTABLE HEIGHT CONTROL STAND WITH THROTTLE CABLE, KILL SWITCH & WIRING, BRAKE SYSTEM & LINES, & THROTTLE ASSEMBLY. IT WILL COME WITH A USED 4 CHANNEL DATA ACQUISITION SYSTEM THAT HAS HEAD TEMPERATURE AND (1) NEW 14MM TEMP SENSOR. THIS ALLOWS YOU TO MEASURE HORSEPOWER, TORQUE, ACCELERATION, HEAD TEMPERATURE, CLUTCH ENGAGEMENT, SHIPPAGE RATIO, WERE TOTAL LOCK-UP OF CLUTCH OCCURS. IT WILL ALSO COME WITH A USED DIGITAL WEATHER STATION SO YOU CAN DO MANUAL S.A.E. WEATHER CORRECTION. IT WILL ALSO COME WITH A SMALL PARTS KIT TO GET YOU STARTED, KEYS, SHIMS, CLUTCH BOLTS, BRAKE BLEEDER, ETC. I DO HAVE A PALLETING FEE INCLUDED, WHICH MEANS, IT WILL BE BOLTED ONTO A PALLET AND SHRINK WRAPPED, THEN TOTALLY ENCLOSED IN PANELLING TO PROTECT IT DURING SHIPPING. YOU WILL NEED A FORKLIFT OR SOMETHING WITH FORKS TO UNLOAD DYNO (900 LBS). NORMALLY DYNO IS POWDER COATED A MEDIUM SILVER, MAINLY BECAUSE MY POWDER COATER DOES BEST BUY SHELVING ALL THE TIME AND THAT IS THE FASTEST IN & OUT OF THERE PLACE. THIS DATA SYSTEM WILL WORK WITH ANY WINDOWS PROGRAM, 95′ TO VISTA. IT DOES NEED A 9 PIN SERIAL PORT OR WITH NEWER COMPUTERS WE USE A USB TO SERIAL PORT ADAPTER ($40.00). THE S.A.E. WEATHER CORRECTION CAN ALSO BE DONE THRU THE COMPUTER THRU USB PORT ALSO. THIS IS THE SIMPLEST DYNO I BUILD. WE HAVE 108 DYNOS IN 27 STATES IN THE U.S. AND ALSO MANY FLYWHEELS AND DATA SYSTEMS CUSTOMERS I ALSO TAKE CARE OF. SEE MY BLOG FOR COMPLETE INFORMATION WWW.HEWITTSINERTIADYNOS.WORDPRESS.COM . THERE IS A LOT MORE PICTURES AND INFORMATION THERE THAT WILL HELP YOU WITH QUESTIONS OR CALL ME AT 1-641-775-3395 OR CELL 1-641-512-3395. I WILL NEED YOUR ZIP CODE TO ESTIMATE FREIGHT???????? THIS BID IS FOR THIS BASIC CLUTCH DYNO. IF YOU WANT ANY OPTIONS LIKE LARGER FLYWHEEL, DIFFERENT DATA SYSTEM, ETC. WE WILL HAVE TO ADJUST PRICE AFTER SALE OF THIS DYNO. THIS DYNO IS FOR ENGINES FROM 5 HP UP TO ABOUT 25 TO 30 HP. DIMENSIONS OF THIS DYNO ARE 36″ X 36″. I CAN HELP YOU WITH DYNO ROOM BASICS BLUEPRINTS OR SPECS. NORMAL PRICE FOR THIS DYNO IS $4100.00 PLUS MY COST OF FREIGHT TO SHIP IT. E-MAIL ME FOR FREIGHT ESTIMATE, HEWITTDYNO@GMAIL.COM OR HEWITTS@NETINS.NET. YOU WILL NEED TO SUPPLY INTERNATIONAL ANGLE OR FLAT MOTOR MOUNT AND COMPLETE COMPUTER SYSTEM. WIRING IN SHOP MUST BE GROUNDED AND I RECCOMEND A SURGE PROTECTOR.

THANKS-STAN HEWITT

AFTER MONEY IS RECEIVED, EXPECT TWO TO THREE WEEKS BEFORE DYNO WILL ARRVIE AT YOUR PLACE. THIS IS A CUSTOM BUILD DYNO AND THERE ARE MANY PARTS OF THE DYNO THAT CAN BE CHANGED AND/OR MODIFIED FOR YOUR APPLICATION, SO WE WILL BUILD TO YOUR SPECS.